Introduction to Heat Presses and Platen Bumps

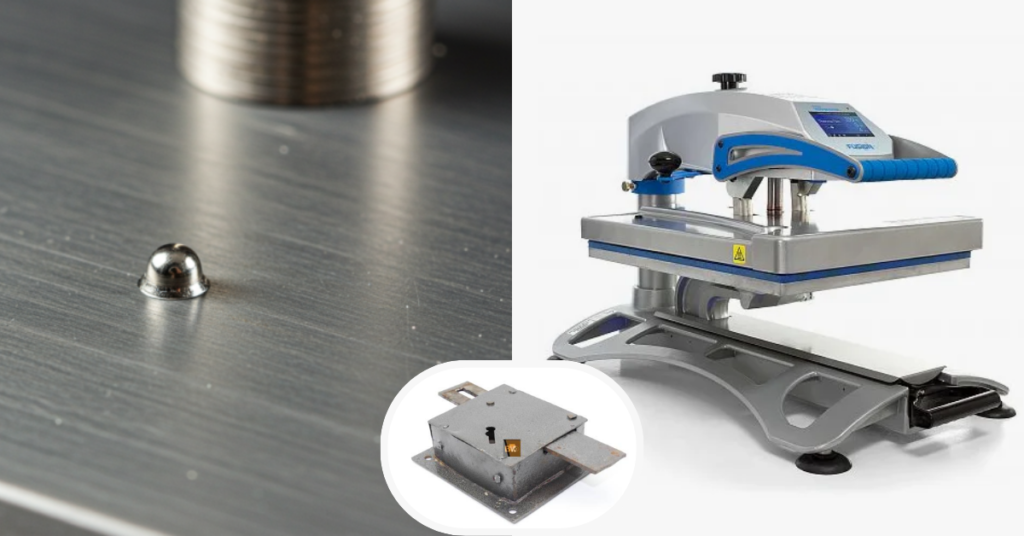

Heat presses are essential tools in the world of crafting and custom apparel. They enable creators to transfer vibrant designs onto various materials, making them a staple for many businesses and hobbyists alike. However, like any piece of equipment, heat presses can encounter issues that affect their performance. One common problem is a small flaw bump on upper heat press platen.

This seemingly minor defect can lead to uneven pressure during pressing, resulting in subpar prints and frustrated users. Understanding what causes these small flaw bumps on upper heat press platen and how to address them is crucial for anyone who relies on a heat press for consistent quality. Whether you’re an experienced professional or just starting out, knowing how to tackle this issue will keep your projects running smoothly. Let’s dive into the heart of this problem so you can get back to creating with confidence!

Common Causes of Small Bump Flaws on Upper Heat Press Platens

Small bump flaws on upper heat press platens can stem from various factors. One common cause is uneven heating. When certain areas of the platen get hotter than others, it can result in localized deformities.

Another factor might be debris trapped between the platen and the heat source. Residue or foreign objects can create pressure points that lead to bumps over time.

Wear and tear also play a role. Continuous use of a heat press causes materials to break down, leading to inconsistencies in surface smoothness.

Temperature fluctuations during operation may contribute as well. Rapid changes can affect how materials expand and contract, resulting in small defects.

Improper maintenance practices can’t be overlooked. Regular cleaning and inspection are essential to prevent issues from developing unnoticed.

How to Identify a Small Bump Flaw

Identifying a small bump flaw on your upper heat press platen requires some attention to detail. Begin by visually inspecting the surface. Look for any irregularities or slight elevations that disrupt the smoothness.

Next, gently run your fingers across the platen. You’ll want to feel for any bumps or inconsistencies in texture. A raised area can often be felt even if it’s not easily seen.

If possible, use a straight edge, like a ruler or level, and place it against the platen. This will help highlight any uneven spots that may be causing issues during pressing.

Perform a test press with scrap material to identify if there are any unintended impressions left behind from the bump. Pay close attention to how evenly pressure is applied across your items; this can reveal hidden flaws as well.

Solutions for Fixing a Small Bump Flaw

Addressing a small flaw bump on your upper heat press platen can be straightforward. Start by checking the surface for debris or residue. A clean platen allows for even heat distribution and minimizes imperfections.

If the bump persists, consider using a fine-grit sandpaper. Lightly sanding down the area can often smooth out any raised spots without damaging the overall structure.

Another effective approach is to apply consistent pressure during pressing. Sometimes, simply adjusting how you position materials can help counteract minor bumps.

For more significant flaws, replacement pads or silicone mats designed specifically for heat presses may offer better results. These accessories are engineered to provide an even surface and improved contact with your materials.

If you’re comfortable with it, investigating beneath the platen could reveal issues like loose screws or misalignments that need addressing for a long-term solution.

Preventing Future Platen Bumps

To prevent future platen bumps, regular maintenance is essential. Keep your heat press clean and free from debris. Residue can lead to uneven surfaces over time.

Check the pressure settings frequently. Incorrect pressure may contribute to bump formation during use. Adjusting it according to manufacturer guidelines ensures even contact across the platen.

Store your heat press in a climate-controlled environment to avoid temperature fluctuations that can warp or damage components. Moisture should also be kept at bay; humidity can exacerbate flaws.

Use high-quality materials for pressing as well. Low-grade items might not withstand repeated heating cycles, leading to potential imperfections on the platen surface.

Consider investing in a protective cover when not in use. This simple step helps shield against dust and physical abrasions that could cause bumps over time.

Conclusion

Addressing a small flaw bump on upper heat press platen may seem daunting at first. However, by understanding the common causes and learning how to identify them, you’ll be in a better position to resolve these issues efficiently. The solutions are often straightforward and involve simple adjustments or repairs that can restore your platen’s functionality.

Preventive measures also play a key role. Regular maintenance and careful handling of your equipment will significantly reduce the chances of encountering a small flaw bump on upper heat press platen in the future. By staying proactive, you ensure better results with every press and increase the longevity of your heat press.

Mastering these aspects not only improves your workflow but also enhances the quality of your products, leading to greater satisfaction for both you and your customers.

Need a guide for testing? Check out the Test Instrument Panel E046 Intelitek Manual.